- Technical parameter

| Specification & type | RMM823RL | RMM623 | RMM523 | RMM423 | |

| Working Width (mm) | Min | 20 | 20 | 20 | 20 |

| Max | 230 | 230 | 230 | 230 | |

| Working Thickness (mm) | Min. | 8 | 8 | 8 | 8 |

| Max | 160 | 160 | 160 | 160 | |

| Number of spindles | 8 | 6 | 5 | 4 | |

| Speed of Spindles (r/min) | 6000 | 6000 | 6000 | 6000 | |

| Cutting circle(max~min)(mm) | First Bottom Spindle | Φ110 - Φ145 | Φ110 - Φ145 | Φ110 - Φ145 | Φ110 - Φ145 |

| First Right side Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | |

| First Left side Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | |

| Second Right side Spindle | Φ110 - Φ200 | ----- | ----- | ----- | |

| Second Left side Spindle | Φ110 - Φ200 | ----- | ----- | ----- | |

| First Top Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | |

| Second Top Spindle | Φ110 - Φ200 | Φ110 - Φ200 | ----- | ----- | |

| Second Bottom Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 ~ Φ200 | ----- | |

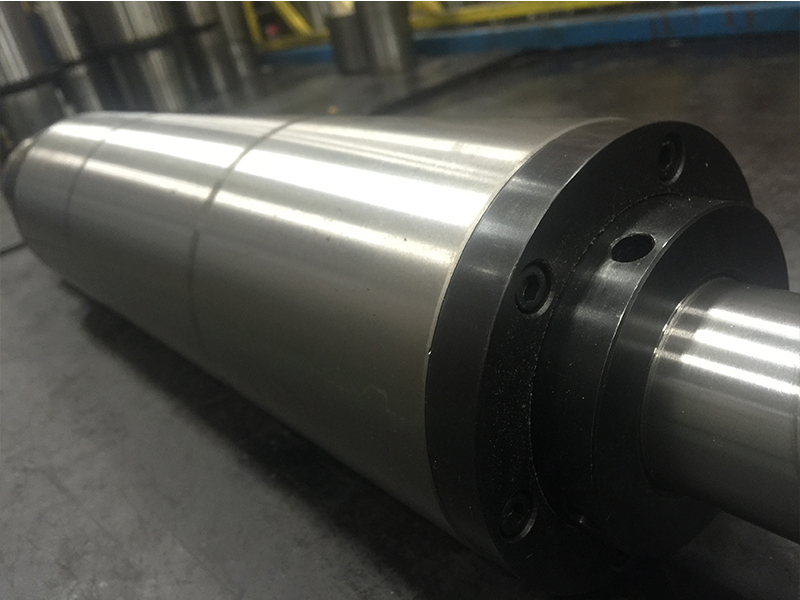

| Spindle diameter(mm) | Φ40 | Φ40 | Φ40 | Φ40 | |

| Basic motor power (kW) | First Bottom Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP |

| First Right side Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | |

| First Left side Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | |

| Second Right side Spindle | 5.5 kW/7.5HP | ----- | ----- | ----- | |

| Second Left side Spindle | 5.5 kW/7.5HP | ----- | ----- | ----- | |

| First Top Spindle | 7.5 kW/10HP | 7.5 kW/10HP | 7.5 kW/10HP | 7.5 kW/10HP | |

| Second Top Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | ----- | ----- | |

| Second Bottom Spindle | 7.5 kW/10HP | 7.5 kW/10HP | 7.5 kW/10HP | ----- | |

| Feed | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 3kW/4HP | 3kW/4HP | |

| Feed beam rise & fall | 1.1kW/1.5HP | 0.75kW/1HP | 0.75kW/1HP | 0.75kW/1HP | |

| Total motor power(KW) | 54.6kW/74HP | 43.25kW/58.5HP | 35.25kW/47.5HP | 27.75kW/37.5HP | |

| Feed speed (m/min) (Inverter for feed ) | 6-30 | 6-30 | 6-30 | 6-30 | |

| Dust outlet diameter(mm) | Φ150 | Φ150 | Φ150 | Φ150 | |

| Overall machine dimensions (L×W×H) (mm) | 4660×1720×1730 | 4660×1720×1730 | 3980×1720×1730 | 3780×1720×1730 | |

| Weight(Tons approx) | 6.3 | 4.6 | 3.8 | 3.4 |

| Specification & type | RMM723U | RMM623U | RMM523U | |

| Working Width (mm) | Min. | 20 | 20 | 20 |

| Max. | 230 | 230 | 230 | |

| Working Thickness (mm) | Min. | 8 | 8 | 8 |

| Max. | 160 | 160 | 160 | |

| Number of spindles | 6+1 | 5+1 | 4+1 | |

| Speed of Spindles (r/min) | 6000 | 6000 | 6000 | |

| Cutting circle (max~min)(mm) | First Bottom Spindle | Φ110 - Φ145 | Φ110 - Φ145 | Φ110 - Φ145 |

| Right side Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | |

| Left side Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110- Φ200 | |

| First Top Spindle | Φ110 - Φ200 | Φ110 - Φ200 | Φ110 - Φ200 | |

| Second Top Spindle | Φ110 - Φ200 | ----- | ----- | |

| Second Bottom Spindle | Φ110 - Φ200 | Φ110 - Φ200 | ----- | |

| Universal spindle | Φ110 -Φ180 | Φ1010 -Φ180 | Φ110 - Φ200 | |

| Universal axle saw blade diameter (mm) (speed 3500r/min.) | Φ350 | Φ350 | Φ350 | |

| Universal axle-mounted cutter length (mm) | 240 | 240 | 240 | |

| Spindle diameter (mm) | Φ40 | Φ40 | Φ40 | |

| Rotation anglefor universal spindle | 360° | 360° | 360° | |

| Basic motor power (kW) | First Bottom Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP |

| Right side Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | |

| Left side Spindle | 5.5 kW/7.5HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP | |

| First Top Spindle | 7.5 kW/10HP | 7.5 kW/10HP | 7.5 kW/10HP | |

| Second Top Spindle | 5.5 kW/7.5HP | ----- | ----- | |

| Second Bottom Spindle | 7.5 kW/10HP | 7.5 kW/10HP | ----- | |

| Universal spindle | 7.5kW/10HP | 7.5kW/10HP | 7.5kW/10HP | |

| Universal spindle rise & fall | 0.18kW/0.25HP | 0.18kW/0.25HP | 0.18kW/0.25HP | |

| Feed | 5.5kW/7.5HP | 5.5kW/7.5HP | 3kW/4HP | |

| Feed beam rise & fall | 1.1kW/1.5HP | 0.75kW/1.1HP | 0.75kW/1.1HP | |

| Total motor power(KW) | 51.28kW/69.25HP | 45.43kW/.1.35HP | 35.43kW/47.85HP | |

| Feed speed (m/min) (Inverter for feed ) | 6-30 | 6-30 | 6-30 | |

| Dust outlet diameter(mm) | Φ150 | Φ150 | Φ150 | |

| Overall machine dimensions (L×W×H) (mm) | 5600×1720×1800 | 4930×1720×1800 | 4700×1720×1800 | |

| Weight(Tons approx) | 6.1 | 4.8 | 4.5 |

Note:Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing all the time.

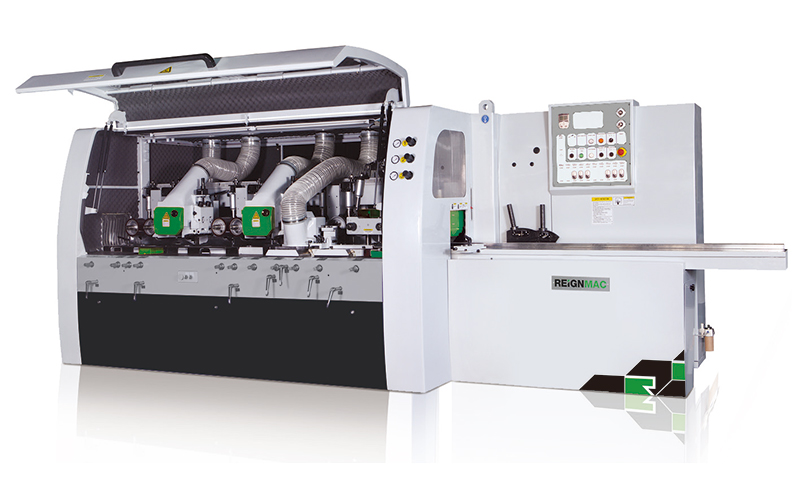

M23 Outstanding character:

1.Inverter feed speed of 6~30m/min(Optional feed speed 9-45m/min).

2.Individual motor to each spindle to ensure maximum power transmission.

3.High precision spindle units with two pairs of high precision bearings each end of the assembly.

4.All main spindle adjustments are carried out from outside the enclosure.

5.Electroplating worktable ,good wear resistance.

6.Short piece driven top feed roller unit for greater feeding control around the right side spindle.

7.A group of side pressure wheels on the right side of the left spindle, adjusted the pressure flexible by pneumatic.

8.As our standard, short pieces device with pneumatic double-direction( press and raise) , you can make the workpieces feeding or back in anytime.

9.in-feed bottom helical roller is more suitable for large deformation and high moisture of the wood to feed.

10.Multi-group bottom driving roller to improve the feed effect.

11.Pneumatic pressure loaded to top feed rollers separately adjustable, for easy of feeding stock with variation in thickness.

12.Adjustable out-feed side pressure plate can meet the different thickness of material output steadily.

13.Manual bed lubrication to reduce friction and improve feeding difficult timbers.

14.Adopting electric component from international class with steady quality.

15.Sealed safety enclose to reduce noise levels, improve extraction and operator safety.

Note:Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing all the time.”

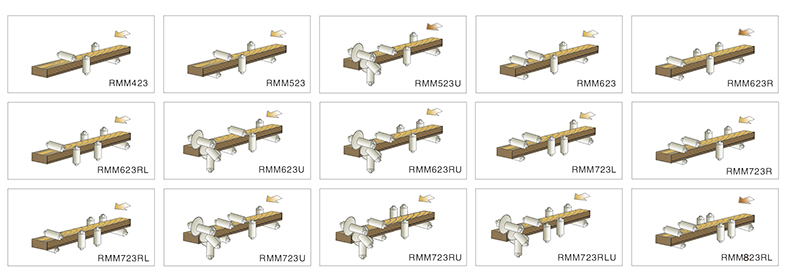

Professional solution for processing Anticorrosive wood ,Wall hanging wooden board, Sauna board etc. for high efficient processing of multi- pieces molding.

Specially with the slicing function, it can enhance the processing efficiency