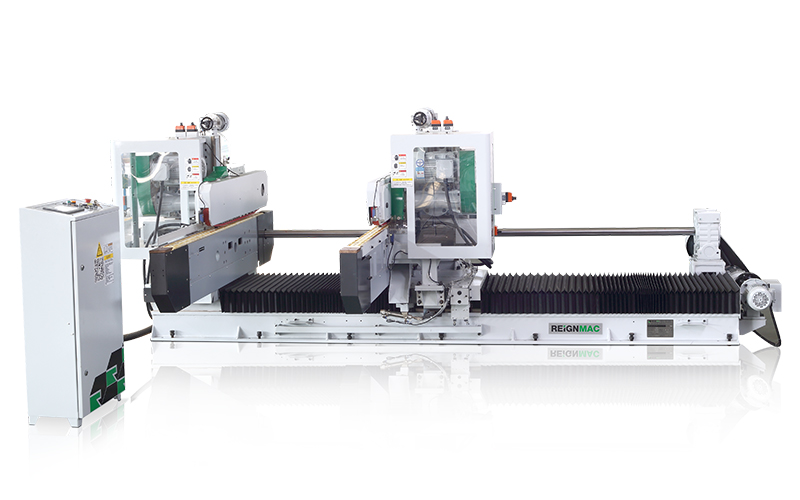

- Technical parameter

| Specification & type | RMD6018E | |

| Working Thickness (mm | 10-50 | |

| Working Width (mm) | 280-1850 | |

| Cutting circle (max~min) (mm) | Left Saw unit | Φ160-Φ200 |

| Right Saw unit | Φ160-Φ200 | |

| Left cut~off Saw | Φ250-Φ300 | |

| Right cut~off Saw | Φ250-Φ300 | |

| Left milling unit | Φ140 - Φ160 | |

| Right milling unit | Φ140 - Φ160 | |

| Spindle diameter (mm) | Left Saw unit | Φ25.4 |

| Right Saw unit | Φ25.4 | |

| Left cut~off Saw | Φ30 | |

| Right cut~off Saw | Φ30 | |

| Left milling unit | Φ40 | |

| Right milling unit | Φ40 | |

| Cutterhead length(mm) | 95 | |

| rotation(r/min) | Scoring saw | 3000 |

| Cut-off Saw | 3000 | |

| Milling unit | 7500 | |

| spindle | 7500 | |

| Basic motor power(kW) | Left Saw unit | 3kW/4HP |

| Right Saw unit | 3kW/4HP | |

| Left cut~off Saw | 5.5kW/7.5HP | |

| Right cut~off Saw | 5.5kW/7.5HP | |

| Left milling unit | 5.5kW/7.5HP | |

| Right milling unit | 5.5kW/7.5HP | |

| Feed | 3kW/4HP | |

| pressure belt lift | 2×0.25kW/0.33HP | |

| Widen | 0.75kW/1.1HP | |

| Total motor power (kW) | 40.25kW/42.63HP | |

| Feed speed (m/min) | 6~ 18 | |

| Dust outlet diameter (mm) | Φ120 | |

| Overall machine dimensions (L×W×H) (mm) | 3500×2350×1500 | |

| Weight (tons approx) (T) | 4 | |

Note:Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing all the time.

D60E outstanding character:

1. Infinitely adjustable feed speeds from 6~18m/min.

2. Adopted widen by high precision liner orbit,machine can run in precision and wearable.It assure the precision when widen the working size,also can guarantee to fit your highly requirement for setting the working width.

3. Through PLC to the control pressure belt and adjustment automatically, make the workpieces more stable and veracious.

4. Setting all of the parameter by PLC, easy to view and control. Reduce labour and the time for setting parameter, improve the productivity effectively.

5. In order to assure every chain board with high precision,we use the high hardness cast iron and treated with high temperature and machining by CNC.

6. Each spindle is configured with read out can display the position of spindle veracious.

7. Adopting electric component from international class with steady quality

8. Adopted excellent material to make of the pressure belts, keep good wearable.

9. Main saw and scoring saw with up and down position,and with sealed safety enclosure to keep the operator safety.

10. adopted pressing rack device which is good for flooring processing.

11. has designed with active pressure feeding belt,it makes the workpieces press again the guiding fence avoid jumping when feeding.

12. Dust proof hood on guide of lathe bed to availably keep thread pole clean.

Note:Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing all the time.

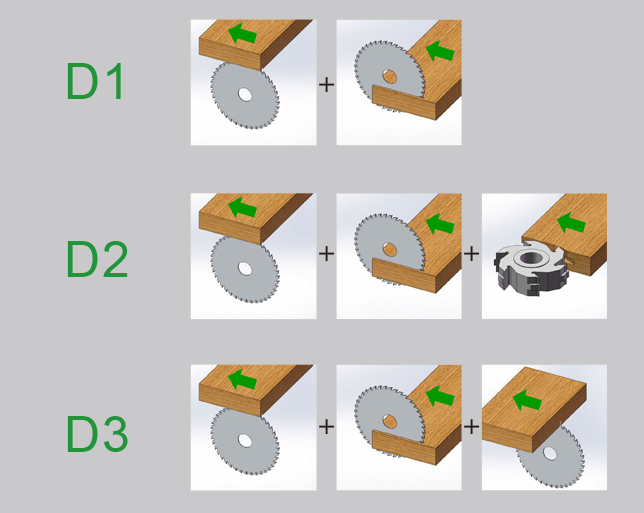

Professional solution for flooring, furniture boards etc. with max length 350mm with light duty profiling for two ends/ continuous processing for trimming.”

Crawler-type for continuously feeding,fold up the inefficiencies years for reciprocating processing.