- Technical parameter

| Specification & model | RMS300 | RMS400 |

| Min length of working piece (install short pressure board) | 280 | 350 |

| Min length of working piece (install long pressure board) | 400 | 500 |

| Max cutting thickness (install short pressure board) | 70 | 110 |

| Max cutting thickness (install long pressure board) | 85 | 135 |

| Max cutting width | 3-300 | 4-400 |

| Max OD of saw | Φ305 | Φ405 |

| Min OD of saw | Φ203 | Φ305 |

| ID size of saw | Φ70 | Φ80 |

| Spindle diameter | Φ50 | Φ60 |

| Spindle speed | 3800 | 3200 |

| Spindle motor | 37KW 22;30 | 45KW 37;55 |

| Lifting motor | 0.37KW | 0.37KW |

| Feed motor | 0.85/1.5KW | 3KW |

| Feed speed (stepless variable to feed) | 7.5-30m/min | 5-35m/min |

| Dust outlet diameter | 2×Φ150 | 2×Φ150 |

| Height of word table from the floor | 740mm | 830mm |

| Work table dimension | 1730×760mm | 1990×850mm |

| Overall size (L×W×H)(mm) | 1890×1625×1458 | 2330×2070×1920 |

| Net weight (kgs) | 2200 | 3500 |

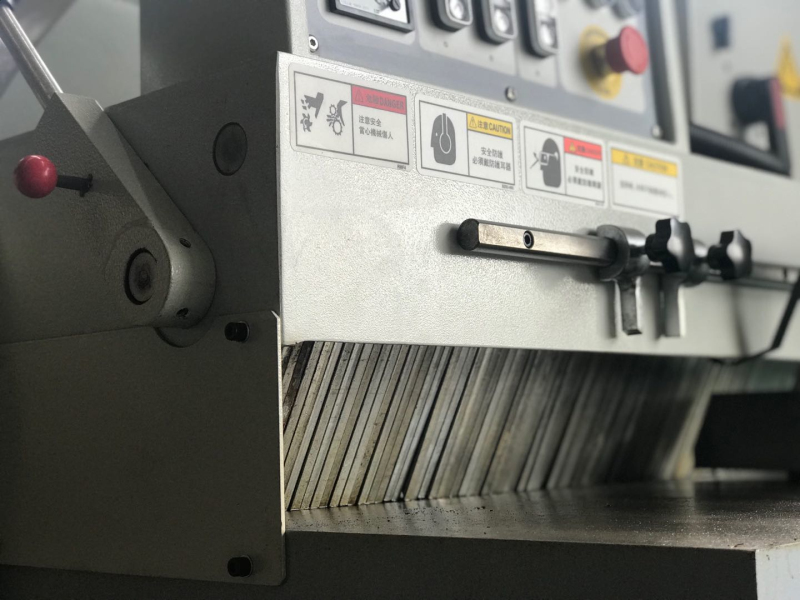

Multi-Rip Saw series RMS Outstanding character:

1. Machine body and table are made of high quality castings,after numberous aging and 5-axis CNC precision machining,stable performance,high percision.

2. Conveyor belt and guide are adopted the special wear-resistant materials with a long life.

3. Spindles with high quality alloy material and imported bearings, precision machining, dynamic balancing processing,ensure stable and reliable operation.

4. Configure automatic oil lubrication system, with a lack of oil, oil leakage shutdown protection, effectively protect the guide rail, chain plate and main sliding parts.

5. Configuring dual top and bottom anti-rebound device and front safety door, effectively prevent the rebound in thin sections and tumor wounding.

6. Pressing device with electric lifting equipment, convenient to adjust and improve productivity.

7. Equipped high torque gear box for feeding, fit for a variety of materials, a variety of thickness of the wood processing re requirements.

8. Power devices configured to open the front safety door after power failure to protect human and machine safety.

9. Feeding pressing wheels and bottom wheels are equipped for RMS400, smoothly feeding,precision increased.

10. Out feed assisted wheels to improve feeding performance for RMS400.

11. RMS400 equipped out ball bearings. Electric components with international class, stable and reliable.

Note:Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing all the time.

Multi-Rip Saw series RMS